Gypsum Board Production Line & Making Machine: A Comprehensive Guide to Manufacturing Processes and Equipment

Table of Contents

1. Raw Material Preparation

- Gypsum Powder: The primary raw material for a gypsum board production line is gypsum powder, sourced from natural deposits or synthetic by-products. In a plasterboard production line, gypsum is processed via mining or collection, then calcined in specialized equipment to form hemihydrate gypsum (plaster of Paris), a key input for gypsum board making machines.

Gypsum Powder Production Line Walkthrough

Watch on YouTube| YouTube

- Additives:

-

- Fibers (e.g., paper pulp, glass fibers) enhance strength in the gypsum board making machine process.

- Setting control agents (retarders/accelerators) regulate hardening time for efficient production on the plasterboard production line.

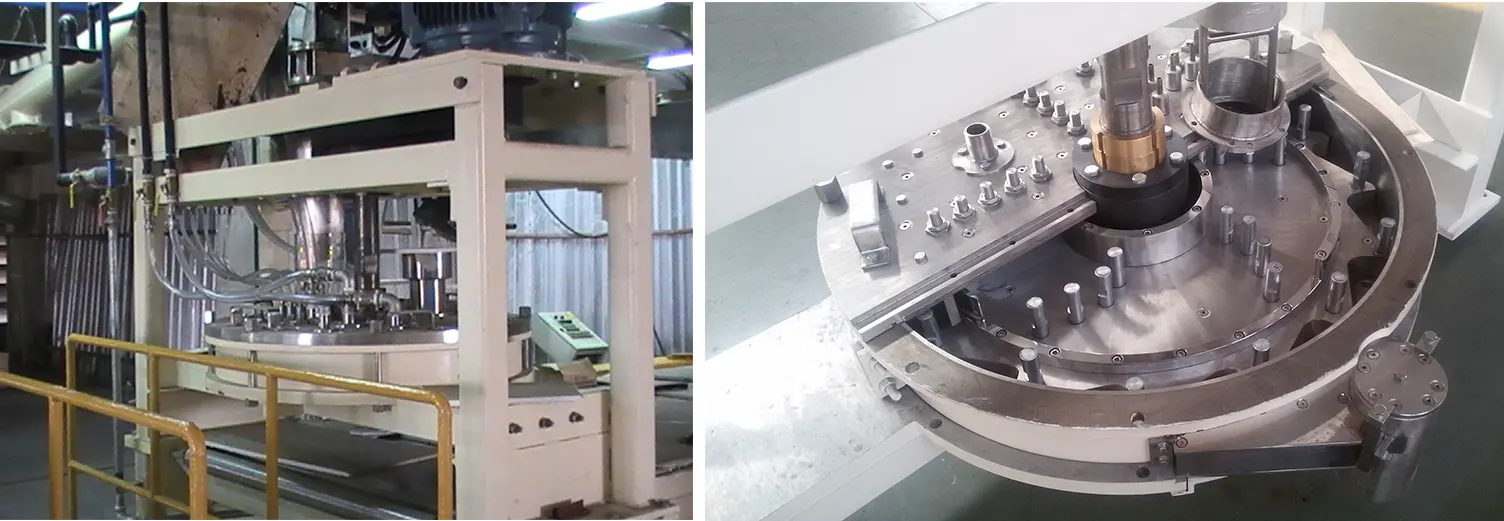

2. Slurry Mixing

Within the gypsum board production line, gypsum powder, water, and additives are fed into a mixer—a critical component of the gypsum board making machine—to form a uniform slurry. The water-to-gypsum ratio is optimized for the board’s hardness, tailored to the specifications of the plasterboard production line.

3. Board Forming

- Paper Feeding: On a plasterboard production line, bottom kraft paper is unwound and fed onto a conveyor belt, a standard step in automated gypsum board production line systems.

- Slurry Deposition: The gypsum slurry is dispensed onto the moving paper via the gypsum board making machine’s deposition mechanism, ensuring even distribution.

- Lamination & Thickness Control: Top paper is layered over the slurry, and rollers in the gypsum board production line press the sandwich to the desired thickness (e.g., 9.5 mm), a function integral to gypsum board making machines.

4. Curing and Hardening

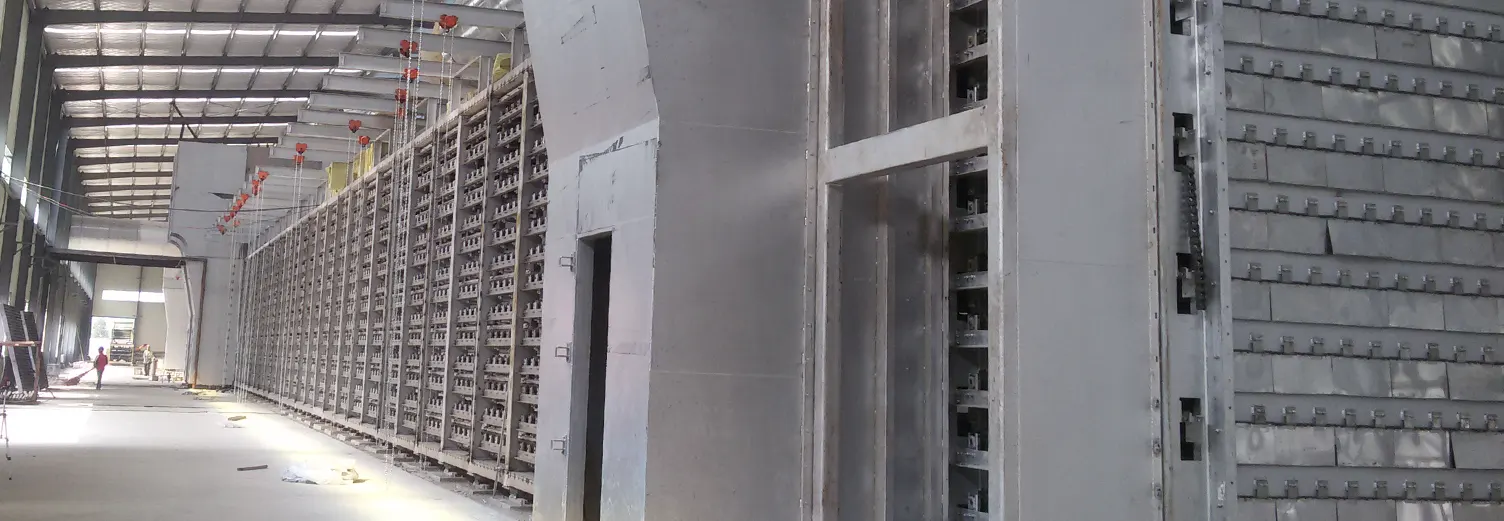

- Formed boards enter a curing chamber within the plasterboard production line, where temperature and humidity are controlled to promote the rehydration of hemihydrate gypsum. This step is essential for the gypsum board production line to ensure structural stability, with gypsum board making machines often integrating automated curing systems.

5. Trimming and Cutting

Post-curing, the continuous gypsum board sheet is cut to standard lengths (e.g., 2.4 m) by precision cutters in the gypsum board production line. Edges are trimmed by the gypsum board making machine to create tapered profiles, a common feature in plasterboard production line outputs for seamless jointing.

6. Quality Inspection

Automated checks on the plasterboard production line verify defects like warping or thickness inconsistencies. Gypsum board making machines may include in-line sensors to test bending strength and fire resistance, critical for gypsum board production line quality control.

7. Packaging and Storage

Certified boards from the gypsum board production line are palletized and wrapped to prevent moisture damage, a final step in the plasterboard production line workflow before storage in dry facilities.

Gypsum Board Production Line Walkthrough

Watch on YouTube| YouTube

If you are interested in gypsum board production lines or planning to invest in such a production line, we offer professional customized services tailored to your needs. We welcome your inquiries at any time.