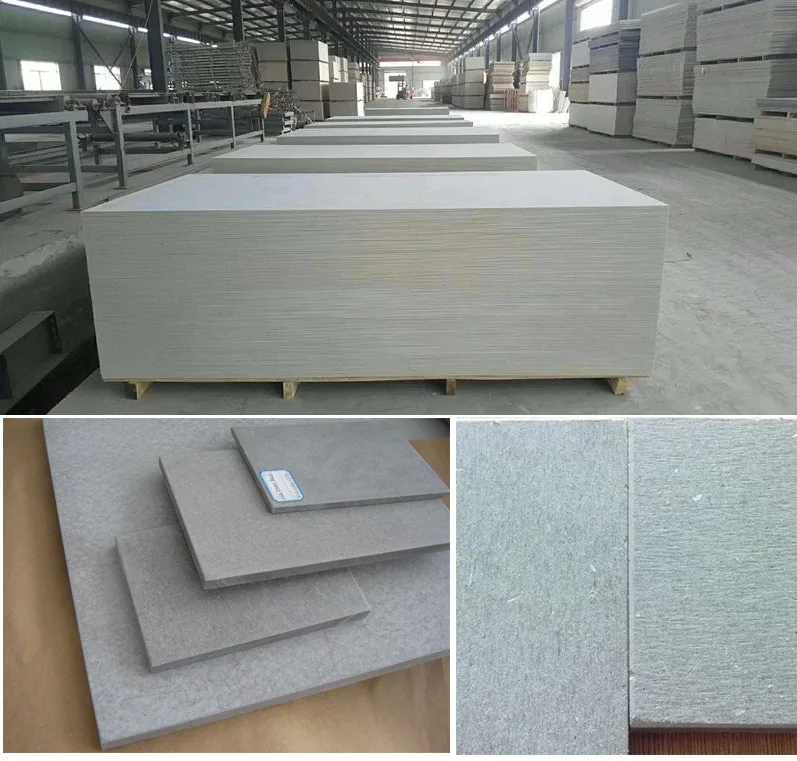

Advanced Fiber Cement Board Production Line | Customizable Solutions for Global Markets

Our Fiber Cement Board Machine is a high-performance solution for producing durable, fire-resistant, and waterproof building materials. Using advanced flow-on process or vacuum extrusion technology, it efficiently combines cement, silica sand, and non-asbestos fibers to create dense, uniform boards.

Fiber cement board production line supports thicknesses from 4–20mm and standard sizes like 1220×2440mm. Features include autoclave curing for superior strength, energy-efficient operation, and eco-friendly recycling of waste. Ideal for exterior cladding, interior partitions, and industrial applications, our factory-direct equipment ensures cost-effective production while meeting global standards (ISO/SGS).

Fiber Cement Sheet Machine Process flow:

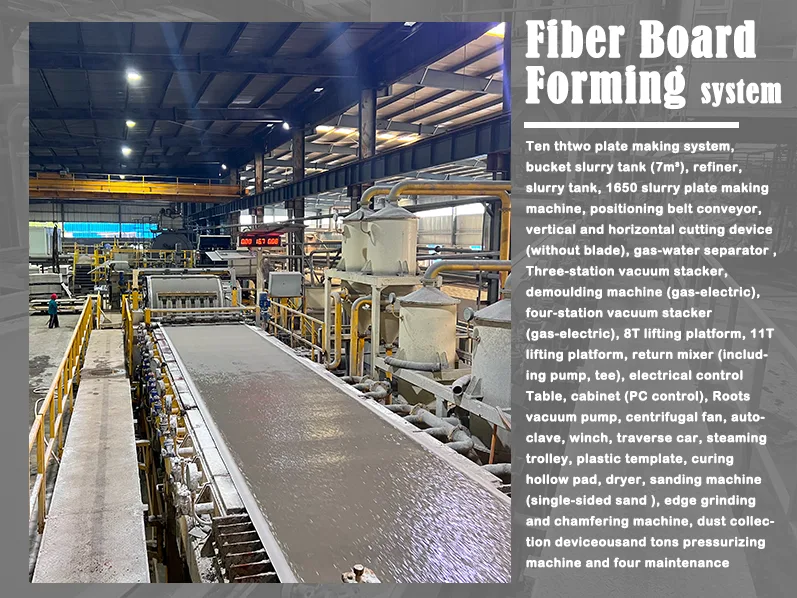

The process begins with non-asbestos fiber pulping (beating, sizing), ensuring uniform fiber dispersion for high-strength boards. Advanced raw material mixing systems combine cement, silica sand, and additives for consistent quality.

A flow-on forming machine creates sheets via automatic cloth washing, precision forming, and seamless connecting. A computer-controlled conveyor system handles stacking and transportation, minimizing manual labor.

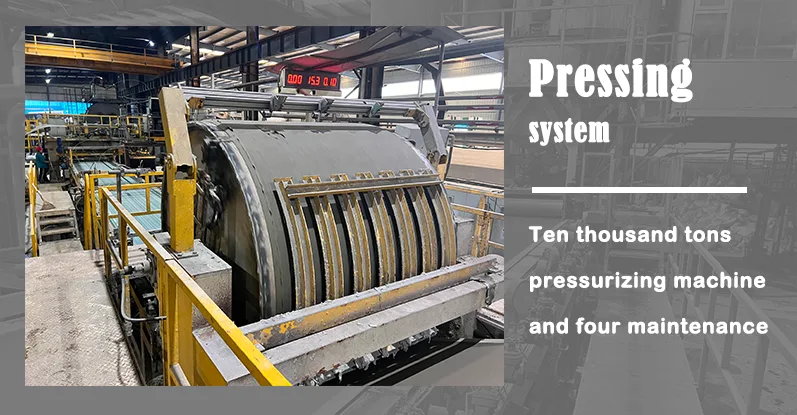

A 10,000-ton hydraulic press with vacuum extrusion technology densifies boards, enhancing durability. Key steps include autoclave curing (pressurization), demoulding, oiling, and conveyor transfer for moisture resistance.

Boards undergo four-cycle curing (steam, drying, cooling, inspection) to meet fireproof (Class A1), waterproof, and high-density (1.2-1.8g/cm³) standards. Final products are sanded and cut to 1220×2440mm or custom sizes.

See How Our Fiber Cement Machines Produce Fireproof Boards – Watch Now!

Cement fiber panel machine specifications

| Parameter | Details |

| Density Range | 1.2-1.8g/cm³ |

| Fire Rating | Class A1 (Non-Combustible) |

| Water Absorption | ≤10% |

| Output | 300,000㎡-800,000㎡/Year |

| Fiber Board Size | 1220×2440mm, 1200×2400mm |

| Board Thickness | 4-20mm |

| Voltage / Power | 380V, 50Hz |

| Raw Material Formula | Cement (50%), Silica Sand (15%), Fiber (15%), Additives (20%) (Adjustable) |

Fibre Cement Board Manufacturing Machinery Composition

① Raw material processing system

② Plate making system

③ Pressing machine

④ Auxiliary Equipment

Applications of Fiber Cement Board

- Construction & Architecture

- Exterior Cladding: Weather-resistant, UV-stable panels for walls, roofs, and facades.

- Interior Partitions: Fire-rated (Class A1) and soundproof boards for offices, homes, and public spaces.

- Flooring: High-density boards for subfloors or decorative finishes.

- Industrial & Commercial Use

- Machine Housing: Protective enclosures for equipment in factories.

- Fire Barriers: Used in warehouses, tunnels, and power plants for flame retardancy.

- Insulation: Combined with mineral wool for thermal and acoustic insulation.

- Decorative & Functional Solutions

- Siding & Trim: Customizable textures and colors for modern or traditional aesthetics.

- Ceiling Systems: Moisture-proof panels for kitchens, bathrooms, and basements.

- Industrial Shelving: Heavy-duty boards for storage racks.

- Specialized Applications

- Agricultural Buildings: Resistant to pests and humidity in barns or greenhouses.

- Transport Infrastructure: Railway platforms, bus shelters, and noise barriers.

- Eco-Friendly Projects: Recyclable, non-asbestos boards for sustainable construction.

Why Choose Us for Your Fiber Cement Board Machine Needs?

- Multi-process flexibility: Flow-on & vacuum extrusion methods for high-density (1.2–1.8g/cm³) boards.

- CE-certified: Compliance with EU safety & quality standards (ISO 9001/SGS).

- Energy-efficient: 30% lower power consumption compared to traditional models.

- Tailored output: Choose between 300,000㎡–800,000㎡ annual capacity.

- Bespoke designs: Adjustable thickness (4–20mm) and formats (1220×2440mm or custom).

- Raw material adaptability: Works with cement, silica sand, and non-asbestos fibers.

- 30+ years in business: Successfully installed 100+ lines in 50+ countries (e.g., Saudi Arabia, India, Germany).

- Turnkey solutions: Full-service support from installation to operator training.

- 24/7 technical assistance: Prompt troubleshooting via WhatsApp/Email.

- Eco-friendly: 95% waste recycling system reduces environmental impact.

- Low carbon footprint: Energy-saving components meet green building standards.

Get Free Quote | Contact us

Get Your Free Customized Quote for Fiber Cement Board Machines