Magnesium Oxide Board Machine

Mgo board production line features advanced machinery. The raw material mixing unit precisely blends components. The forming machine creates boards with accurate dimensions. Our high – efficiency drying equipment rapidly removes moisture. The cutting machine cuts boards to desired sizes. This automated and integrated line ensures continuous, high – quality production of Mgo boards for various applications.

DEYI MGO BOARD PRODUCTION LINE

MGO Board Making Machine Flow Chart

Our Mgo board production line operates through a series of precise and automated steps. First, raw materials go through an automatically feeding metering system, ensuring accurate amounts are used. Then, they enter the mixing stage where components are thoroughly blended. Next, the mixture is automatically fed into the mould. The forming process shapes the boards, followed by pre – pressing to give initial firmness. After that, the boards are cut to the required length. They are then automatically loaded onto cage vehicles and sent for the first curing to start the hardening process. A full – automatic mould – releasing mechanism is used, and then the boards undergo a second curing for enhanced strength. Edge cutting refines the edges, and sanding gives a smooth finish. Finally, a strict quality control (Q.C.) is carried out, and the qualified Mgo boards are packaged for delivery.

Why Choose Our Mgo Board Machinery?

1. Cutting-Edge Technology

- Automatic Mgo Board Forming Machine: Fully automated systems for seamless production of magnesium oxide boards, reducing labor costs and increasing output.

- Computer-Controlled Mgo Board System: Real-time monitoring for consistent quality in thickness, density, and surface finish.

- High-Speed Mgo Board Machinery: Achieve 4000 sheets per shift production with our state-of-the-art mgo board press machine and drying equipment.

2. Versatile Material Handling

- Mgo Cement Board Machine: Ideal for manufacturing cement-based MgO boards with superior strength and fire resistance.

- Fiber-Reinforced Mgo Board Production Line: Add fibers to enhance flexibility and impact resistance for industrial applications.

- Lightweight Mgo Board Machinery: Produce panels weighing as low as [X] kg/m² without compromising performance.

3. Eco-Friendly & Sustainable

- Eco-Friendly Mgo Board Production Line: Uses non-toxic materials and energy-efficient processes, aligning with green building standards.

- Fireproof Mgo Board Machine: Certified fire-resistant boards for safe construction in commercial and residential projects.

Applications of Our Mgo Board Solutions

- Construction Mgo Board Machine: Perfect for walls, ceilings, and partitions in high-rise buildings.

- Interior Decoration Mgo Board Production Line: Create stylish, moisture-resistant panels for homes and hotels.

- Industrial Mgo Board Machinery: Durable boards for factories, warehouses, and infrastructure projects.

- Fire-Resistant Partition Mgo Board Equipment: Compliant with global safety regulations for public spaces.

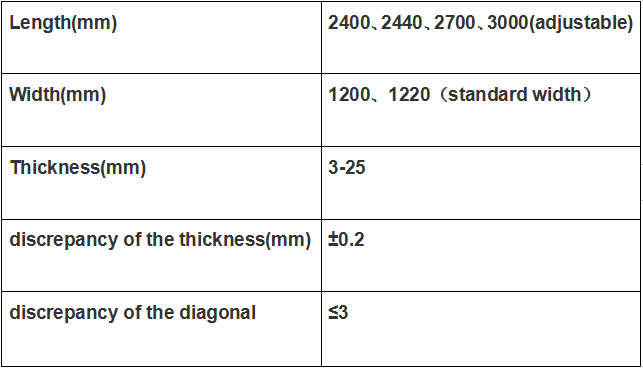

Magnesium Board Specifications

Customized Solutions & Support

- Custom Mgo Board Machinery Solutions: Tailored configurations to match your production capacity and budget.

- Competitive Mgo Board Machine Price: Cost-effective options for small-scale startups to large enterprises.

- Global Mgo Board Machine Suppliers: Comprehensive after-sales service, installation, and operator training.

Main Section Exibition

Powder conveying system

Raw material mixing system

Raw material mixing system

Forming System

Demoulding System

Cutting System

Cutting System

Dust Collection System

Contact us

Contact us today to explore our mgo board machine range or request a quote for a magnesium oxide board production line. Elevate your manufacturing efficiency with reliable, high-performance equipment.