XPS EPS Cement Panel Production Line

XPS foam board production line

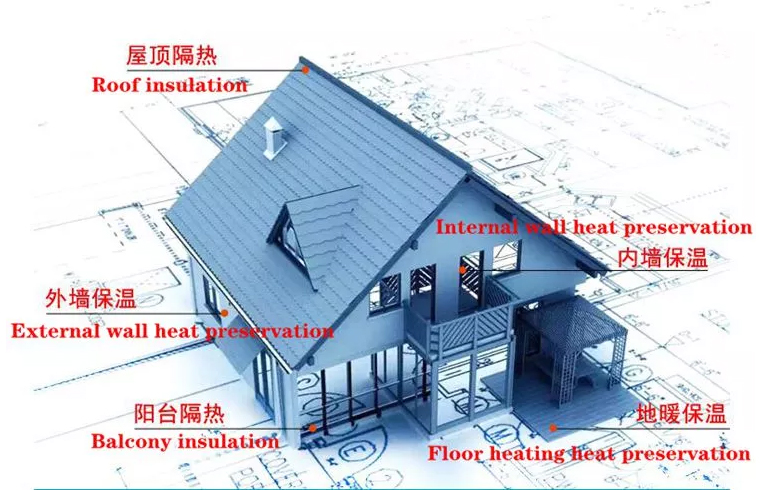

It is widely used in the following fields which is recognized as the environmental type thermal insulation material in the market currently

1. waterproofing, heat preservation and heat insulation of walls and roofs of residential buildings, office, industrial plants and other construction industries;

2. heat insulation and heat preservation of steel-structure workshop, iron-skin house and colorful wave tile;

3. Insulation board used in freezer, keep cold and waterproof;

4. moisture proof, heatproof and soundproof for the floor heating project under the floor;

5. heatproof and heat preservation for the ventilation pipes of central air conditioning

6. Anti-freezing and heaving material for concrete water conveyance channels in water conservancy projects (such as the South-to-North Water Diversion Project in China);

7. Antifreezing and heat preservation for road, railway, airport, square and other subgrade projects.

1.XPS Board Production Line

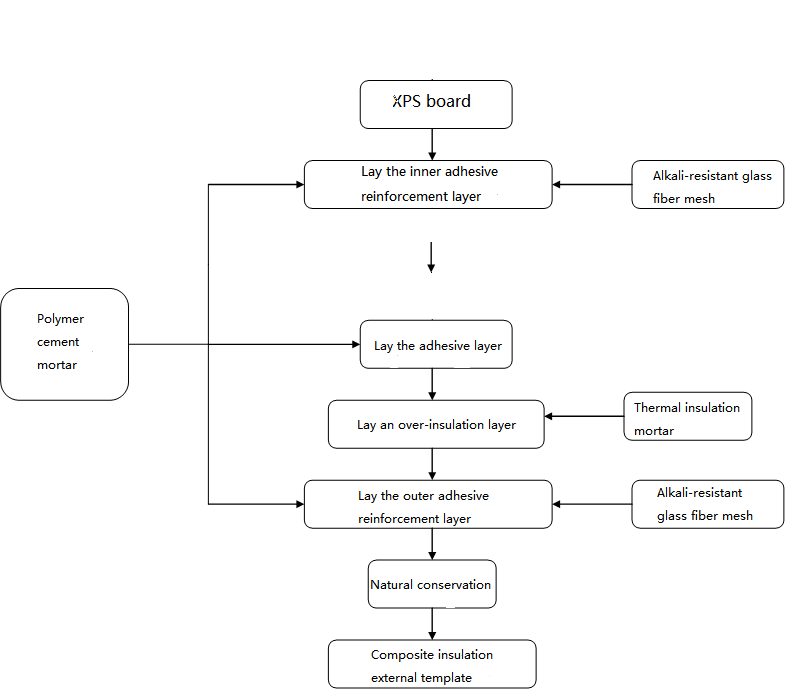

2. XPS EPS Cement Panel Production Line

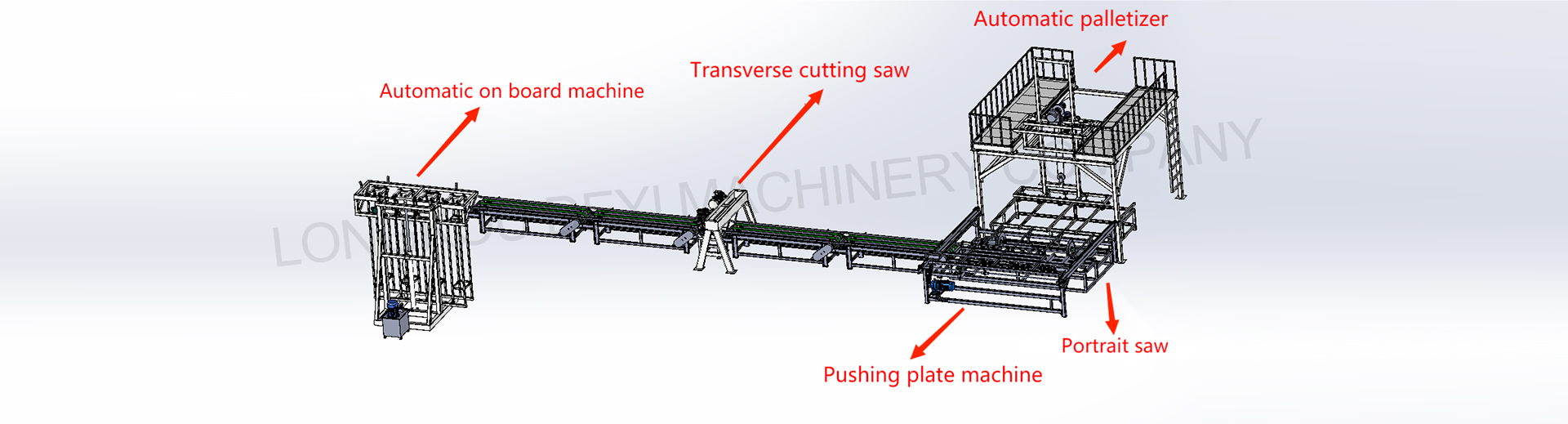

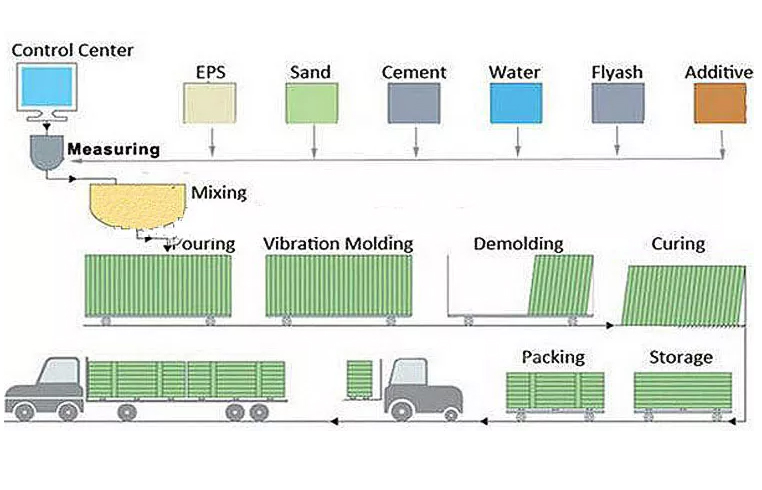

XPS EPS Cement Panel Production Line is mainly composed of electronic metering device, dry powder mortar mixer, slurry mixer, work lifting frame, smoothing device, conveying equipment and cutting machine. Dry powder mortar mixer and slurry mixer adopt automatic batching and electronic metering, with high automation and accurate metering. The molding equipment has the characteristics of reasonable structure design, convenient production and operation, short molding cycle, high production efficiency, and good product quality.

2 The thickness of wall more thinner

3 More easy to install, take a modular assembly, saving installation time

4 Higher strength, more anti-aging Higher energy efficiency More waterproof

5 The fireproof performance meets the national A standard and it is non-combustible

FAQ

Q:. Why I choose your company?

A: a) We are the Leading XPS EPS cement panel production line Manufacturer in China.

b) We have made foam machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

f) One year guarantee and lifetime maintenance.

Q: What should we prepare except material?

A: You should prepare workshop, water line, electric line, compress air (if you need, we can help you buy air compressor).

We can supply workshop layout drawing according to your workshop.