All Products

BUILDING EQUIPMENT MANUFACTURER

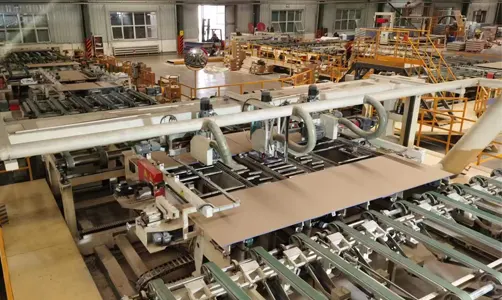

LONGKOU DEYI specialize in manufacturing building materials production equipment, offering the following core products:

- Gypsum Board Production Line: Designed for producing gypsum boards (paper-faced, decorative) suitable for construction partitions, ceilings, and other applications.

- MGO Board Machine: Manufactures fire-resistant, moisture-proof, and eco-friendly MgO-based boards for interior/exterior decoration and furniture.

- XPS Cement Composite Board Production Line: Combines XPS insulation with cement for panels ideal for external wall insulation and roofing.

- EPS Cement Sandwich Board Machine: Produces lightweight, soundproof sandwich panels with EPS cores, used in temporary structures and prefab housing.

- Fiber Cement Board Production Line: Creates high-density, weather-resistant fiber cement boards for exterior cladding, industrial buildings, and interior finishes.

- 3D Wall Panel Machine: Customizes textured 3D decorative panels to meet high-end architectural aesthetics.

Gypsum board production line

Gypsum board is made of building gypsum (natural gypsum, desulfurized gypsum, phosphogypsum) and protective paper as the main raw materials, and add a certain proportion of water, starch, admixture and foaming agent, after mixing, forming, cutting, Various specifications of lightweight decorative materials made by processes such as drying, trimming and wrapping.

Magnesium oxide board production line

Magnesium oxide board is made of magnesium oxide, magnesium chloride, water as the main raw materials, wood chips, perlite, etc. are used as auxiliary fillers to mix and stir, and glass fiber cloth, non-woven cloth, etc. are used as reinforcing and toughening materials. In addition, additives can be added. Rolling and extrusion equipment flow production line production, under natural temperature conditions (10-35 ℃ is best), through its own exothermic reaction, the material is solidified.

EPS/XPS cement insulation board machine

XPS EPS Cement Panel Production Line is mainly composed of electronic metering device, dry powder mortar mixer, slurry mixer, work lifting frame, smoothing device, conveying equipment and cutting machine.

EPS cement sandwich board machine

The lightweight prefabricated EPS cement wallboard machine is designed to adapt to the recent development trend of building materials. The material is made of cement and foam material. It has light weight features and has a large volume of demand in the market. Our company has boldly designed this highly automated production line.

Fiber cement board production line

The main components of fiber cement board are cement and wood fiber, using cement as the basic material and adhesive, and wood fiber as the reinforcing material, through pulping, embryo forming, curing, drying, cutting, spraying, packaging and other processes. Of plates.

3D Panel Machine

Looking for a 3D panel machine? Our factory, one of the leading 3D panel machine manufacturers, offers a range of options. From 3D wall panel machines and 3D wall panel making machines to specialized eps 3D panel machines and 3D eps wire mesh panel machines